Products

Hybrid Transformer

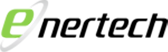

Hybrid Cast-resin Transformer

As a new technology-driven, low-loss, high-efficiency transformer, it boasts easy maintenance, outstanding short-circuit mechanical strength, moisture resistance, flame retardancy, and suitability for facilities with heavy load fluctuations like power supply installations.

Short-circuit Strength The epoxy resin cast coil is designed for high electrical and mechanical strength, ensuring resilience against short circuits, external impacts, and vibrations.

Short-circuit Strength

The epoxy resin cast coil is designed for high electrical and mechanical strength, ensuring resilience against short circuits, external impacts, and vibrations.

Impulse withstand voltage The epoxy resin insulation effect and split winding design result in excellent impulse withstand voltage characteristics.

Impulse withstand voltage

The epoxy resin insulation effect and split winding design result in excellent impulse withstand voltage characteristics.

Flame retardant The epoxy resin exhibits excellent flame retardancy, reducing the risk of electric arc-induced fires, and it is self-extinguishing and fire-resistant.

Flame retardant

The epoxy resin exhibits excellent flame retardancy, reducing the risk of electric arc-induced fires, and it is self-extinguishing and fire-resistant.

Insulation efficiency The Epoxy Resin coil significantly improves insulation resistance and blocks moisture from the outside.

Insulation efficiency

The Epoxy Resin coil significantly improves insulation resistance and blocks moisture from the outside.

Overload Capability The cast coil with Epoxy resin has a high thermal time constant factor, therefore it can endure much higher overloads for a short time.

Overload Capability

The cast coil with Epoxy resin has a high thermal time constant factor, therefore it can endure much higher overloads for a short time.

Stability It is suitable for rapidly fluctuating loads such as electric power supply facilities and rolling facilities.

Stability

It is suitable for rapidly fluctuating loads such as electric power supply facilities and rolling facilities.

Eco-Friendly Since oil is not used, there is no risk of environmental pollution due to oil spills.

Eco-Friendly

Since oil is not used, there is no risk of environmental pollution due to oil spills.

Maintenance Oil replacement and separate fire fighting equipment are not required compared to inlet transformers.

Maintenance

Oil replacement and separate fire fighting equipment are not required compared to inlet transformers.

| Installation place | indoor | |||

| Rated Frequency | 50/60Hz | |||

| Insulation kind | B or F | |||

| Allowable winding temperature | 80℃, 100℃ | |||

| Applicable standard | KSC 4311, IEC 60726 | |||

| Primary rated voltage | 22.9 kV | 6.6/3.3 kV | ||

| Primary TAP Voltage | F23.9-R22.9-21.9-19.9 | F6.9-R6.6-6.3-6.0-5.7 | ||

| F3.45-R3.3-3.15-3.0-2.85 | ||||

| Secondary rated voltage | 6.6/3.3kV | 380V-220V | 380V-220V | |

| Constant | 3 Phase | |||

| Angular displacement | Dzn | |||

| kVA Range | up to 3MVA | |||

Dimensions

3P 22.9kV-LV

| Capacity | Impedance | Voltage regulation | No load current | Efficiency | Dimensions | Weight | ||

|---|---|---|---|---|---|---|---|---|

| (kVA) | (±10%) | (%) | (%) | (Load 50%) | W | D | H | (kg) |

| 100 | 4.5 | 2.2 | 2.0 | 98.9 | 1340 | 850 | 1340 | 1100 |

| 200 | 4.5 | 2.0 | 1.7 | 99.0 | 1400 | 860 | 1580 | 1350 |

| 300 | 5.5 | 1.7 | 1.5 | 99.1 | 1540 | 890 | 1530 | 1780 |

| 400 | 5.5 | 1.6 | 1.4 | 99.2 | 1560 | 910 | 1720 | 2300 |

| 500 | 6.5 | 1.5 | 1.3 | 99.2 | 1560 | 910 | 1720 | 2450 |

| 600 | 6.0 | 1.4 | 1.2 | 99.3 | 1740 | 950 | 1800 | 3100 |

| 750 | 6.0 | 1.4 | 1.1 | 99.3 | 1780 | 980 | 1900 | 3250 |

| 1000 | 6.0 | 1.3 | 1.0 | 99.4 | 1920 | 1000 | 2170 | 4500 |

| 1250 | 7.0 | 1.3 | 1.0 | 99.4 | 1980 | 1055 | 2370 | 5100 |

| 1500 | 7.5 | 1.2 | 0.9 | 99.5 | 2240 | 1200 | 2560 | 7100 |

| 2000 | 8.0 | 1.1 | 0.8 | 99.5 | 2430 | 1300 | 2700 | 8800 |

| 2500 | 8.0 | 1.1 | 0.7 | 99.5 | 2570 | 1400 | 2890 | 11000 |

※ The above specifications may vary depending on the installation location and options.

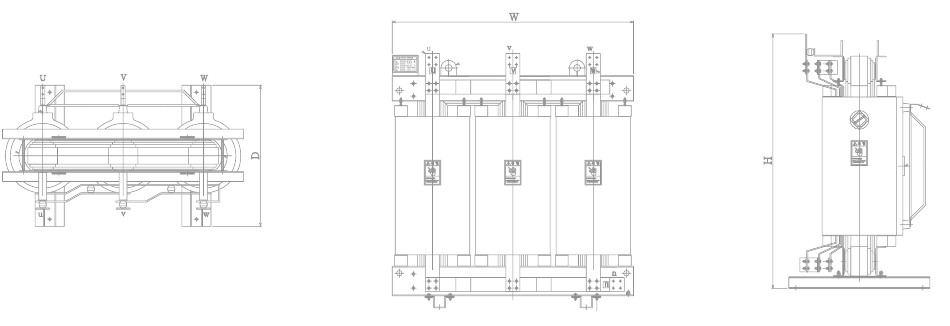

Hybrid Oil-immersed Transformer

It’s a cutting-edge transformer that optimizes working conditions, significantly reduces noise, and achieves low loss and high efficiency through double Zig-Zag winding and high permeability silicon steel plates.

Steel Core The steel core incorporates high-permeability directional silicon steel plates, remaining age-resistant, to minimize load-free current, loss, and vibration while reducing noise through precision machining.

Steel Core

The steel core incorporates high-permeability directional silicon steel plates, remaining age-resistant, to minimize load-free current, loss, and vibration while reducing noise through precision machining.

Winding Winding methods are tailored to transformer types, utilizing high-quality conductors capable of withstanding allowable current, temperature rise, and external short-circuit forces. Designs optimize efficiency while considering insulation hierarchy and mechanical strength.

Winding

Winding methods are tailored to transformer types, utilizing high-quality conductors capable of withstanding allowable current, temperature rise, and external short-circuit forces. Designs optimize efficiency while considering insulation hierarchy and mechanical strength.

Tank The tank, made of cold-rolled steel plates, withstands internal pressure and is engineered to resist deformation from external shocks during transportation or other events.

Tank

The tank, made of cold-rolled steel plates, withstands internal pressure and is engineered to resist deformation from external shocks during transportation or other events.

Insulation The insulation effect is maximized by using the best insulation material to withstand abnormal voltage and breakdown tests.

Insulation

The insulation effect is maximized by using the best insulation material to withstand abnormal voltage and breakdown tests.

Overload Capability Shot peening and powder coating prevent the tank from rusting.

Overload Capability

Shot peening and powder coating prevent the tank from rusting.

Insulating oil To prevent the aging of insulating oil, small and medium-sized transformers use a dehydrating breather containing silica gel, and large transformers are equipped with a conservator.

Insulating oil

To prevent the aging of insulating oil, small and medium-sized transformers use a dehydrating breather containing silica gel, and large transformers are equipped with a conservator.

| Installation place | indoor / outdoor | |

| Rated Frequency | 50/60Hz | |

| Insulation kind | A | |

| Allowable winding temperature | 55℃ | |

| Applicable standard | KSC 4317, IEC 60076-1 | |

| Primary rated voltage | 22.9 kV | 6.6/3.3 kV |

| Primary TAP Voltage | F23.9-R22.9-21.9-19.9 | F6.9-R6.6-6.3-6.0-5.7 |

| F3.45-R3.3-3.15-3.0-2.85 | ||

| Secondary rated voltage | 380/220V, 440V | |

| Constant | 3Phase | |

| Angular displacement | Dzn | |

| Rated capacity | up to 3MVA | |

Dimensions

3P 22.9kV-LV

| Capacity | Impedance | Voltage regulation | No load current | Efficiency | Dimensions | Weight | ||

|---|---|---|---|---|---|---|---|---|

| (kVA) | (±10%) | (%) | (%) | (Load 50%) | W | D | H | (kg) |

| 100 | 6.0 | 1.7 | 3.5 | 99.0 | 1420 | 930 | 1480 | 1600 |

| 200 | 5.1 | 1.7 | 3.5 | 99.1 | 1350 | 950 | 1480 | 1600 |

| 300 | 5.5 | 1.6 | 3.0 | 99.2 | 1410 | 1000 | 1540 | 2000 |

| 400 | 4.3 | 1.6 | 3.0 | 99.2 | 1350 | 980 | 1560 | 2050 |

| 500 | 5.2 | 1.6 | 3.0 | 99.2 | 1390 | 1040 | 1590 | 2300 |

| 600 | 5.5 | 1.5 | 3.0 | 99.3 | 1600 | 1070 | 1710 | 3150 |

| 750 | 5.0 | 1.5 | 3.0 | 99.3 | 1600 | 1070 | 1710 | 3150 |

| 1000 | 5.6 | 1.4 | 3.0 | 99.3 | 1750 | 1150 | 1800 | 4000 |

| 1250 | 5.8 | 1.4 | 3.0 | 99.4 | 1800 | 1300 | 2000 | 5300 |

| 1500 | 6.0 | 1.4 | 2.5 | 99.4 | 1800 | 1300 | 2000 | 5300 |

| 2000 | 6.0 | 1.3 | 2.5 | 99.4 | 1900 | 1450 | 2030 | 5850 |

| 2500 | 6.9 | 1.3 | 2.5 | 99.5 | 2550 | 1750 | 2370 | 7300 |

※ The above specifications may vary depending on the installation location and options.